Inglés UdeA - Cabezote - WCV(JSR 286)

Inglés UdeA - Cabezote - WCV(JSR 286)

Signpost

Signpost

Interna Ingles

Interview with Jeremiah Abblett on HTML5

Interview with Jeremiah Abblett on HTML5

Interview with Jeremiah Abblett on HTML5

Check out our interview with Jeremiah Abblett, founder of WebSnack.ing, for a sneak peak of the hottest topic at this year’s conference and find out why Jeremiah thinks the future of multi-channel experiences lies with HTML5.

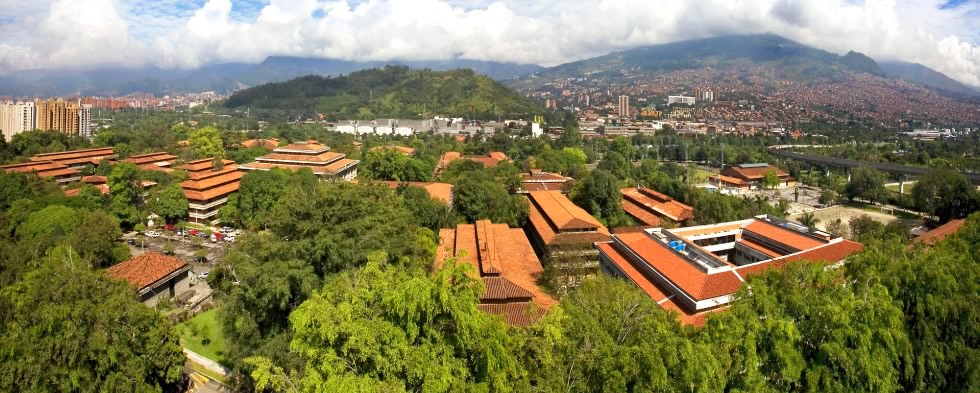

La Universidad de Antioquia es una institución estatal del orden departamental, que desarrolla el servicio público de la Educación Superior, creada por la Ley LXXI del 4 de diciembre de 1878 del Estado Soberano de Antioquia, organizada como un Ente Universitario Autónomo con régimen especial, vinculada al Ministerio de Educación Nacional en lo atinente a las políticas y a la planeación del sector educativo y al Sistema Nacional de Ciencia y Tecnología; goza de personería jurídica, autonomías académica, administrativa, financiera y presupuestal, y gobierno, rentas y patrimonio propios e independientes; se rige por la Constitución Política, la Ley 30 de 1992, las demás disposiciones que le sean aplicables de acuerdo con su régimen especial, y las normas internas dictadas en ejercicio de su autonomía.

La Universidad tiene su domicilio en la ciudad de Medellín, Departamento de Antioquia, República de Colombia. Con arreglo a la Ley y al presente Estatuto, puede establecer seccionales y dependencias en cualquier lugar del territorio nacional, y crear o formar parte de corporaciones, fundaciones y otras instituciones públicas o de economía mixta.

La Universidad de Antioquia tiene por objeto la búsqueda, desarrollo y difusión del conocimiento en los campos de las humanidades, la ciencia, las artes, la filosofía, la técnica y la tecnología, mediante las actividades de investigación, de docencia y de extensión, realizadas en los programas de Educación Superior de pregrado y de posgrado con metodologías presencial, semipresencial, abierta y a distancia, puestas al servicio de una concepción integral de hombre.

Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal manera que logró hacer un libro de textos especimen. No sólo sobrevivió 500 años, sino que tambien ingresó como texto de relleno en documentos electrónicos, quedando esencialmente igual al original. Fue popularizado en los 60s con la creación de las hojas "Letraset", las cuales contenian pasajes de Lorem Ipsum, y más recientemente con software de autoedición, como por ejemplo Aldus PageMaker, el cual incluye versiones de Lorem Ipsum.

Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal manera que logró hacer un libro de textos especimen. No sólo sobrevivió 500 años, sino que tambien ingresó como texto de relleno en documentos electrónicos, quedando esencialmente igual al original. Fue popularizado en los 60s con la creación de las hojas "Letraset", las cuales contenian pasajes de Lorem Ipsum, y más recientemente con software de autoedición, como por ejemplo Aldus PageMaker, el cual incluye versiones de Lorem Ipsum.

Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal manera que logró hacer un libro de textos especimen. No sólo sobrevivió 500 años, sino que tambien ingresó como texto de relleno en documentos electrónicos, quedando esencialmente igual al original. Fue popularizado en los 60s con la creación de las hojas "Letraset", las cuales contenian pasajes de Lorem Ipsum, y más recientemente con software de autoedición, como por ejemplo Aldus PageMaker, el cual incluye versiones de Lorem Ipsum.

Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal manera que logró hacer un libro de textos especimen. No sólo sobrevivió 500 años, sino que tambien ingresó como texto de relleno en documentos electrónicos, quedando esencialmente igual al original. Fue popularizado en los 60s con la creación de las hojas "Letraset", las cuales contenian pasajes de Lorem Ipsum, y más recientemente con software de autoedición, como por ejemplo Aldus PageMaker, el cual incluye versiones de Lorem Ipsum.

Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto de relleno estándar de las industrias desde el año 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal manera que logró hacer un libro de textos especimen. No sólo sobrevivió 500 años, sino que tambien ingresó como texto de relleno en documentos electrónicos, quedando esencialmente igual al original. Fue popularizado en los 60s con la creación de las hojas "Letraset", las cuales contenian pasajes de Lorem Ipsum, y más recientemente con software de autoedición, como por ejemplo Aldus PageMaker, el cual incluye versiones de Lorem Ipsum.

- Lista no ordenada

- Lista no ordenada

- Lista no ordenada

- Lista no ordenada

- Lista ordenada

- Lista ordenada

- Lista ordenada

- Lista ordenada

- Lista ordenada

- Lista ordenada

- Lista ordenada

ño 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal manera que logró hacer un li

ño 1500, cuando un impresor (N. del T. persona que se dedica a la imprenta) desconocido usó una galería de textos y los mezcló de tal manera que logró hacer un li

| Tbala | sdlkjasdlk |

| saldkjaslkdjasdlk | lsadkjalskdjaslk |

| saldkjasldkjsalk | asldkjasdlasjdlkasd |

Titul h1

Título h2

Título h3

Título h4

Título h5